In conversation with Suzanne Oude Hengel, founder of Knit in Motion

We have the pleasure of interviewing Suzanne Oude Hengel, the visionary founder and creative director behind Knit in Motion (KiM), a knit development and consultancy studio that has quickly made its mark in the footwear industry. Rooted in innovation, research, and experimentation, KiM serves as an independent force, helping brands explore new possibilities in knitwear and push the boundaries of what’s possible in design and functionality. With over seven years of experience working with renowned brands like Timberland, Rothy’s, and On Running, Suzanne combines technical expertise with bold, hands-on development that redefines the intersection of knitting and footwear.

At the core of Suzanne’s work is a hybrid approach that blends design with technical mastery, focusing on problem-solving through knit engineering. Specializing in Stoll flat knitting technology, she has recontextualized knitting for footwear upper construction and manufacturing. Her background in Product Design at ArtEZ University of the Arts in Arnhem, and further training at institutions like TextielLab and the Santoni Pioneer Project, have provided her with the knowledge and creative drive to rethink how knitted textiles can be applied in innovative ways.

We are so pleased to be here with another fabulous interview, this time with Knit in Motion (KiM), an incredibly advanced knitting design entity that steps outside the borders of typical knitting. For those of us who aren’t aware of the impact of knitting engineering, could you give us your take on the significance of knitting engineering? How does it impact the art sphere and the practical sphere?

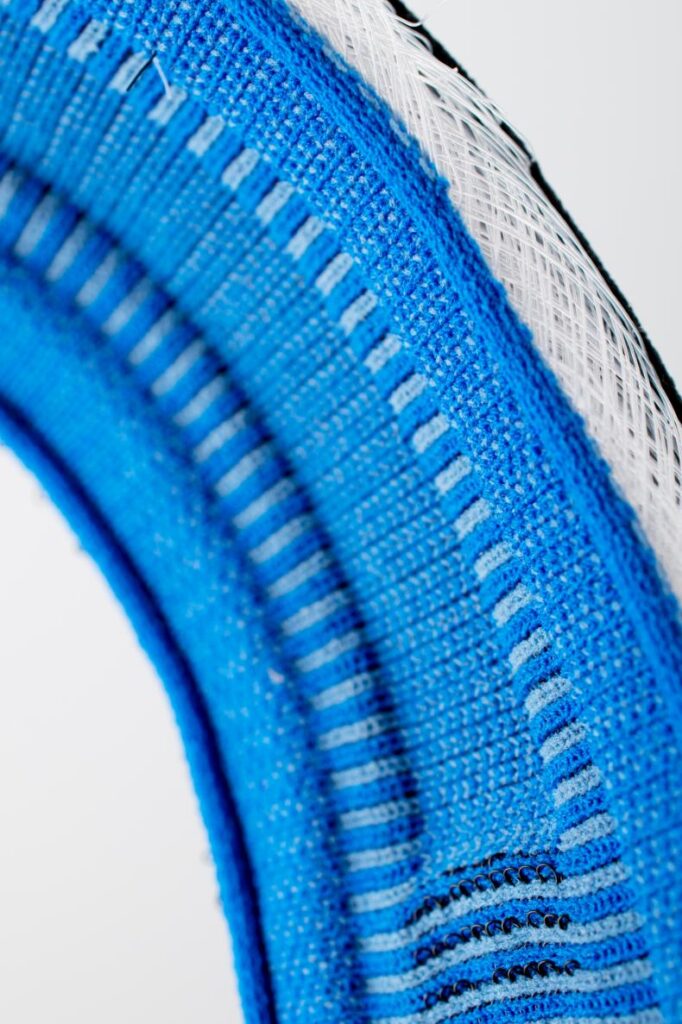

Knitting is really unique process where you can engineer the material you want, but also shape that material. There is so much potential in knitting; from combining multiple functionalities into a single fabric to even knitting a 3D, completely seamless shoe. At KiM we sit in-between the worlds of design and knit engineering— we are more than product designers. Our knowledge of technical knitting gives us more room to experiment with design and also what’s possible within knit engineering. All of our work will always have a designer’s eye and a feel for colour, but at the same time, we’re also really interested in pushing technical boundaries.

Please tell us about how Knit in Motion started and how the entity has grown into what it is today.

I started a designer with a fascination for textiles and material development. It’s fascination that drove me to seek out opportunities that allowed me to learn more about knitting and industrial knitting, including working as a knit technician. I started off freelancing under my own name, but realised that the company was becoming bigger than just me. KiM eventually became its own entity, taking on its own aesthetic and voice.

What sort of considerations are there when it comes to engineering the knit design with footwear? How does the knit become optimized for that particular function?

Footwear is a highly functional product that really needs to perform in specific ways. So functionality is a key part of designing knitting footwear, and when you zoom into what those key functionalities are, you begin find questions and problems to solve. For example, a shoe usually has different zones that all need to function differently, like some places you need support, comfort, breathability, or durability.

All those elements need to combine in one shoe. And because they can often be completely opposite to each other, this can sometimes be a challenging endeavor. At KiM, we approach these problems from both a design and knit engineering perspective. We look at different yarns and how they can add to performance as well as knit structures themselves.

How does Knit in Motion innovate their methods to explore new ways to knit and enhance the technology? What future goals are there for KiM?

A longterm goal for KiM is to become a hub for knit innovation and development— a place where design meets engineering and R&D. In the meantime, we’ve focused on building a solid foundation that we can grow from. In practical terms, we’ve invested heavily in learning and expanding our knowledge base with trainings and close relationships with mentors (thanks for your continued support, Rudi Rots and Sarena Huizinga!). As a smaller startup, we started from scratch when creating KiM.

In the beginning we were really concerned with setting up the basic needs for operation, like getting access to equipment, sourcing yarns, etc. But even at that stage, we prioritised taking on projects that interested us. We get excited about projects that force us to push boundaries in some way. Often it’s a bigger brand looking for a way to step outside of their comfort zone. It could also be looking at the way factories work, and offering a new insight into their processes. Our perspective is that knitting technology can be used to solve a range of problems across industries.

While a lot of my personal work has been with footwear, KiM works within varied industries, like automotive interiors, architecture, product design, in addition to footwear. Collaboration is a core value for us, and we believe that a big component of innovation is working across disciplines and sharing information. By challenging the way things are typically done, we can find new ways and paths for design and manufacturing.

What are some of the milestones and achievements that have been notable for Knit in Motion?

The first major milestone was purchasing an industrial Stoll knitting machine for KiM. It had been a longterm goal that we reached much more quickly than we had anticipated. I remember thinking at that time, “I can’t believe this is real!” Last year, I was a featured designer in Timberland’s Future 23 collection. This collaboration represented a major achievement for us. We used our unconventional approach to design as well as our expertise in technical knitting to reimagine the iconic 6-inch boot as a knitted spacer.

Taking these ideas and knitting techniques into production with a big brand like Timberland was challenging, but ultimately proved that our methods are achievable within large-scale manufacturing. Knit in Motion has allowed me to do what I love and work with like-minded people internationally and within the Netherlands. Because sharing ideas and collaboration is so important for us, building strong and lasting relationships with other creatives and the brands that we work with is probably the most rewarding achievement for us.

Knit in Motion: https://www.knitinmotion.com/